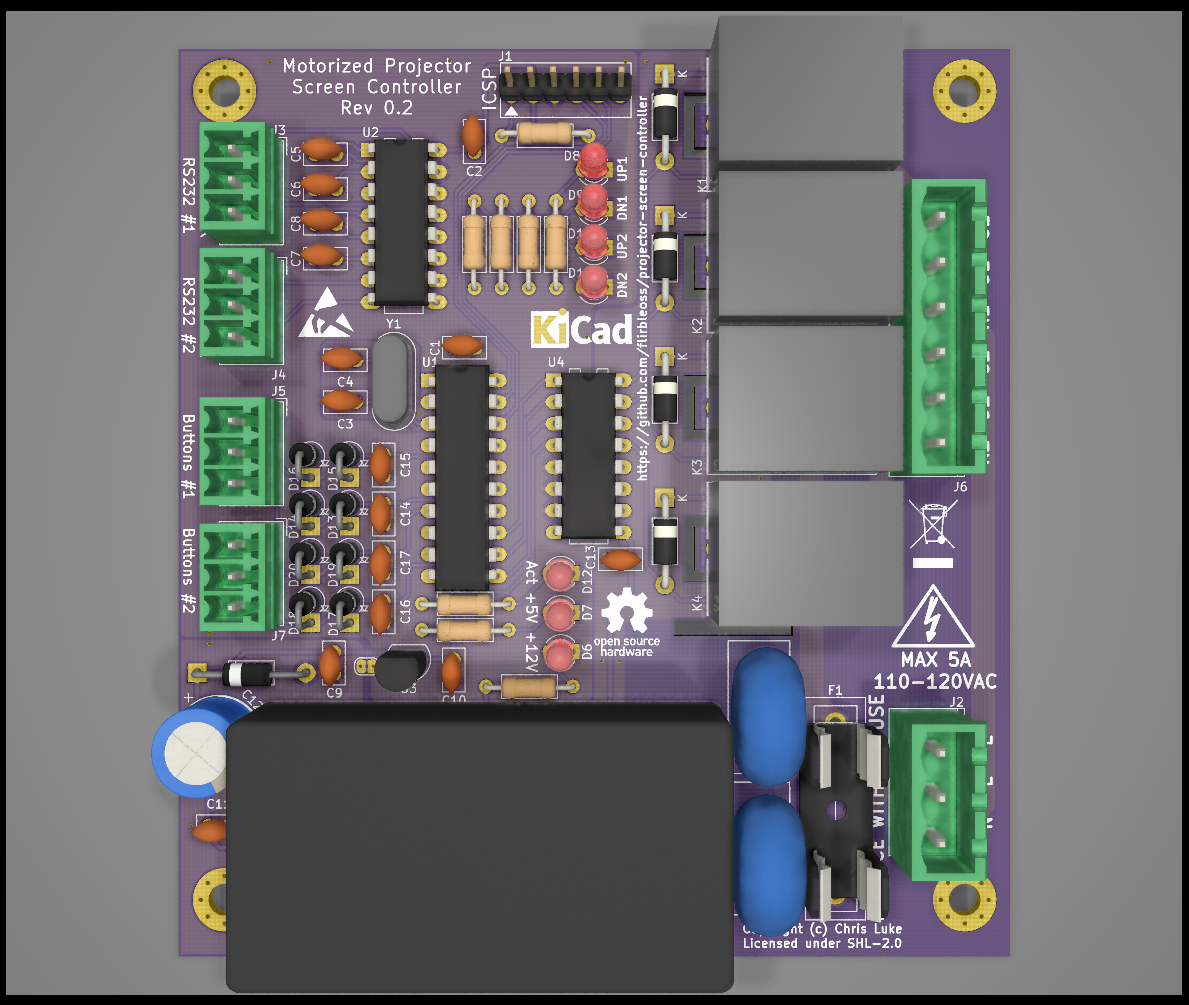

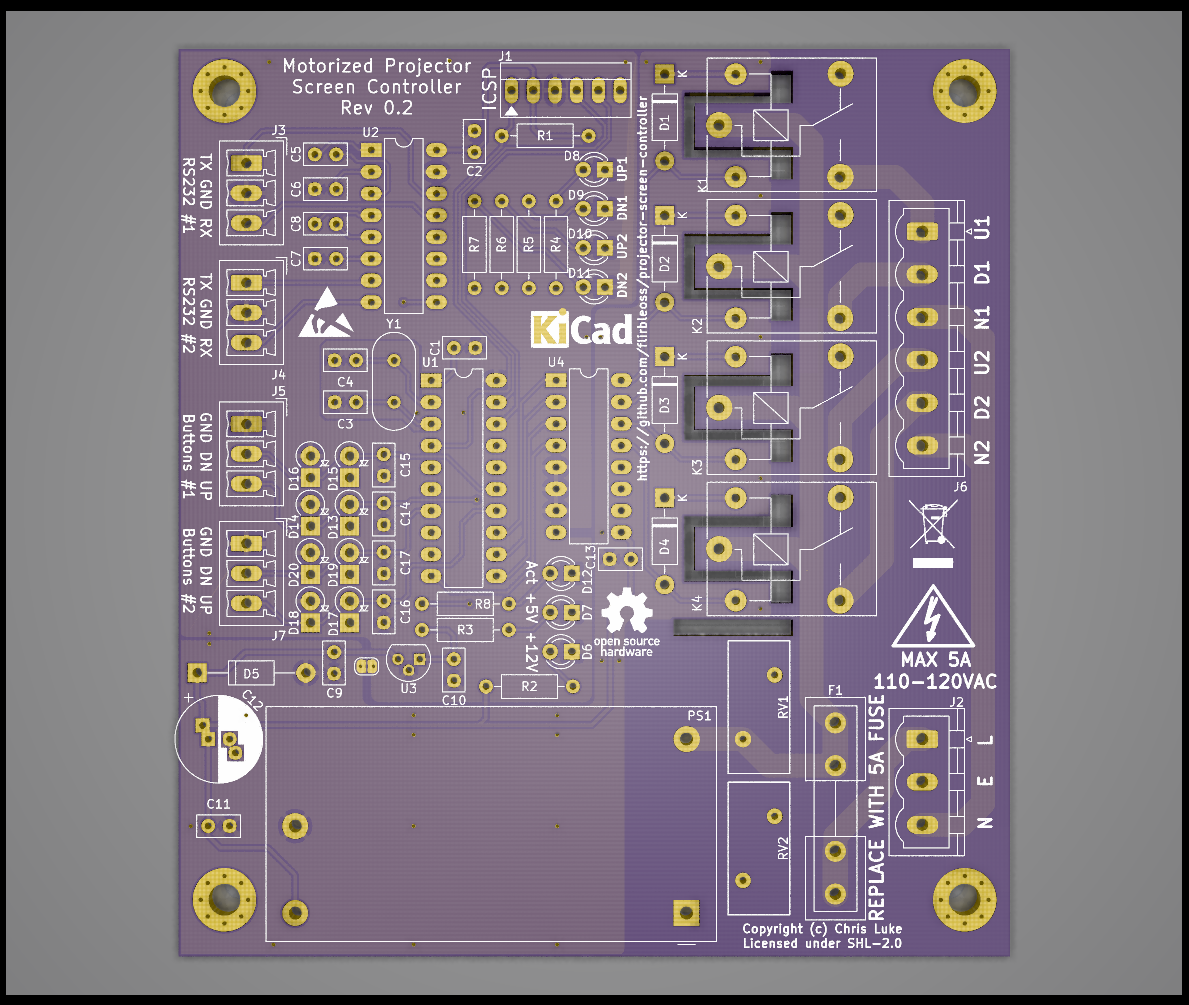

Motorized Projector Screen Controller

Simple controller for basic motorized projector screens. An almost-drop-in

replacement for the Da-Lite SCB-100.

Status: Work in progress

Tired of the commercial screen controller letting out its magic smoke every

couple of years and not content with the $400 replacement cost, I decided to

make my own almost-drop-in replacement with more emphasis on electronic

protection than the commercial variant seems to have.

In my analysis of both SCB-100s that failed, it appeared a transient condition

upset the MAX232 driver such that it causes a dead-short between the 5v and 0v

rails. The charge pump capacitors of the MAX232 chip are adjacent to the

ULN2003 relay driver and the 12V decoupling capacitor. The design relies on

the diodes in the ULN2003 for back-EMF suppression, which I speculate may not

be adequate for the off-brand relays in use in both of my SCB-100s (an online

search reveals other specimens have relays from a more reputable brand,

however.) Finally, the switching power supply module is soldered to the back

of the logic board. While there is a plastic divider between the boards, there

is only a few milimeters of space and line voltage spikes may well cause

interference; additionally there are several places where line voltage and

signal voltage traces come closer than I would be comfortable with.

It is my conclusion therefore that the failures are likely caused by

insufficient physical isolation and insufficient transient back-EMF

suppression.